称重传感器力矩补偿

Do you know if you have an accurate force reading?

In most applications it is difficult, if not impossible, to calculate or even estimate the effect of misalignments on the precision of a force measurement system. Moment sensitivity introduces errors into force measurements whenever forces cannot be applied precisely on-axis.

- The LowProfile™ design by Interface has the intrinsic capability of canceling moment loads because of its radial design.

- The radial flexure beams are precision machined to balance the on-axis loading.

- The gages are precisely placed so that strains due to on-axis loads are additive and strains due to moment loads tend to cancel under actual moment loading.

- Interface uses eight gages, as opposed to the four used by many manufacturers, which helps to further minimize error from the loads not being perfectly aligned.

- Slight discrepancies between gage outputs are carefully measured and each load cell is adjusted to further reduce extraneous load sensitivity, to meet the specifications in the table below.

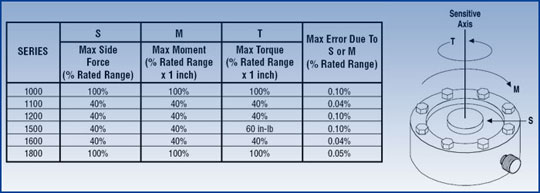

Resistance to Extraneous Loads

The Interface Low Profile design provides optimum resistance to extraneous loads to insure maximum operation life and minimize reading errors. The above chart tabulates maximum allowable extraneous loads that may be applied singularly without electrical or mechanical damage to the cell and the maximum error that can be expected from side forces or bending moments. Several loads can be tolerated simultaneously if the total combined load is not more than 100% of the allowable maximum extraneous load.

Only Interface guarantees maximum extraneous load error and physically adjusts every load cell. The Interface 1200 Series cells have eccentric load sensitivity less than ±0.25% of reading per inch, and the 1000, 1100, and 1600 Series are further adjusted to come in at less than ±0.1% of reading per inch. Most competing load cells will have extraneous load error 10 times higher (or even more) than with a superior Interface load cell.